Laser technology has come a long way since its inception in the mid-20th century. From being used primarily in scientific experiments, lasers now have a wide range of applications in fields such as manufacturing, communication, and medicine. One of the latest advancements in laser technology is the diode pumped fiber laser. In this blog post, we will explore what a diode pumped fiber laser is, how it works, and its advantages over traditional lasers.

What is a Diode Pumped Fiber Laser?

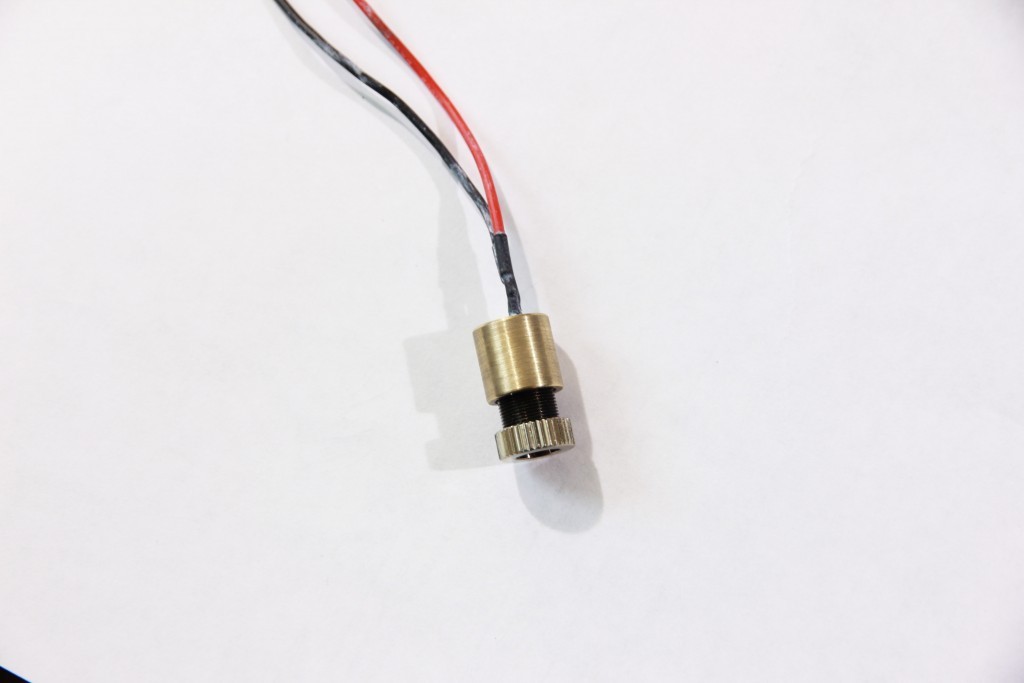

A diode pumped fiber laser is a type of laser where the gain medium is an optical fiber doped with rare-earth elements such as dysprosium or erbium. The erbium-doped fiber laser (EDFL) was the first diode pumped fiber laser to be developed in the 1990s. With the development of novel rare-earth-doped fibers, a variety of fiber lasers has since been developed.

How Does a Diode Pumped Fiber Laser Work?

A diode pumped fiber laser works by using a series of diodes to generate a high-energy beam of light that then pumps the rare-earth-doped fiber. The energy from the diodes excites the rare-earth ions within the fiber, which generate a population inversion. This population inversion creates an amplification effect as photons travel through the fiber. The amplified light travels back and forth within the fiber, causing stimulated emission to occur in the form of a laser beam.

Advantages of a Diode Pumped Fiber Laser

There are several advantages of using a diode pumped fiber laser over traditional lasers, such as:

1. High Efficiency

Diode pumped fiber lasers have higher efficiency compared to traditional lasers. The diodes used to pump the rare-earth-doped fiber are more efficient than the flash lamps used in traditional lasers, resulting in less heat loss and a more efficient use of energy.

2. Compact Design

The compact design of diode pumped fiber lasers makes them easily incorporated into a variety of systems. Traditional lasers require large, bulky components which limit their application in areas where space is restricted.

3. High Beam Quality

Diode pumped fiber lasers have high beam quality, meaning the laser beam has a narrow diameter and is highly concentrated. This makes them an ideal choice for applications such as cutting, drilling, and welding.

4. Long Lifespan

Diode pumped fiber lasers have a longer lifespan compared to traditional lasers. Due to their efficient use of energy and compact design, there is less wear and tear on the components, resulting in a longer lifespan.

Applications of Diode Pumped Fiber Lasers

Diode pumped fiber lasers have a wide range of applications in various industries, including:

1. Manufacturing

Diode pumped fiber lasers are commonly used in manufacturing for cutting, welding, and drilling. They provide a high-quality, precise laser beam that results in clean, precise cuts and welds.

2. Communication

Diode pumped fiber lasers are used in long-distance communication applications such as fiber-optic networks. These lasers transmit information over long distances by using light to encode data onto a fiber-optic cable.

3. Medical

Diode pumped fiber lasers are used in medical applications such as laser surgery, dermatology, and ophthalmology. They provide a precise, clean laser beam that can safely target specific areas of the body.

Conclusion

Diode pumped fiber lasers are a significant advancement in laser technology that provides high efficiency, compact design, high beam quality, and long lifespan. These lasers have a variety of applications in different industries such as manufacturing, communication, and medicine. As technology continues to advance, we can expect to see continued growth in the use of diode pumped fiber lasers.