In today's rapidly evolving manufacturing industry, the demand for advanced materials and cutting-edge technology has never been higher. Companies are constantly in search of innovative solutions that can help them improve efficiency, reduce costs, and enhance the quality of their products. Laser Cut Carbon Fiber has emerged as one such groundbreaking technology that is set to revolutionize the manufacturing processes across various industries.

Laser Cut Carbon Fiber, a state-of-the-art process that utilizes high-powered lasers to precisely cut and shape carbon fiber materials, has become increasingly popular due to its ability to deliver superior results compared to traditional cutting methods. By harnessing the power of laser technology, manufacturers can now achieve unprecedented levels of precision, speed, and flexibility in their production processes.

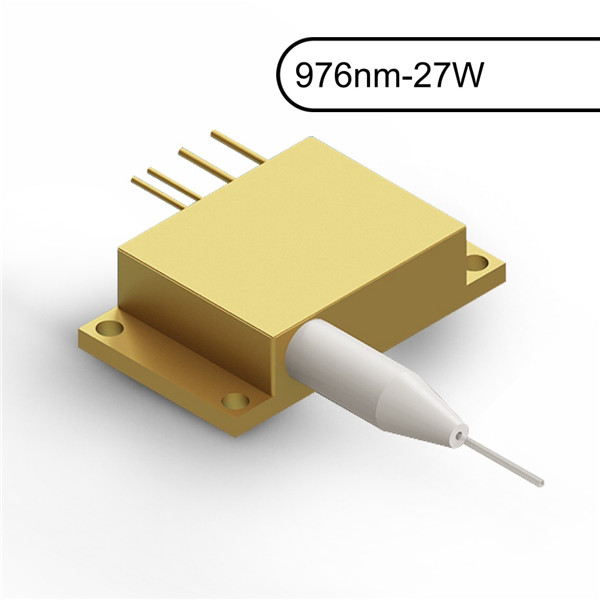

Leading the way in the development and implementation of Laser Cut Carbon Fiber technology is [Company Name], a global leader in laser solutions. Founded in 2003, [Company Name] is committed to the mission of "Let the dream drive the light", and has set the vision of becoming the "Global leader in laser solutions, with the value of "Outstanding innovation". The company provides a wide range of laser products and solutions, including Diode laser, Fiber laser, and Ultra-fast laser, to meet the diverse needs of its global customers.

Carbon fiber, renowned for its exceptional strength-to-weight ratio and durability, has become a go-to material for a wide range of applications, including aerospace, automotive, marine, and sports equipment. However, working with carbon fiber has its challenges, particularly when it comes to cutting and shaping the material with precision and efficiency. Traditional cutting methods such as sawing or milling can often result in fraying, delamination, or inconsistent cuts, leading to wasted materials and increased production time.

Laser Cut Carbon Fiber technology offers a compelling solution to these challenges. By using a high-powered laser beam to vaporize the material's atomic bonds, manufacturers can achieve clean, precise, and uniform cuts without causing any damage to the surrounding areas. This not only eliminates the need for secondary finishing processes but also allows for intricate designs and complex geometries to be achieved with ease.

Moreover, laser cutting provides a non-contact process, which means that there is minimal to no tool wear, reducing maintenance costs and downtime. The speed and accuracy of laser cutting also contribute to increased productivity, allowing manufacturers to fulfill orders in a fraction of the time it would take using traditional methods.

In addition to the manufacturing benefits, Laser Cut Carbon Fiber technology also has the potential to unlock new design possibilities and product innovations. With the ability to cut and shape carbon fiber with unmatched precision, designers and engineers can explore new avenues for lightweight, high-performance products that were previously unattainable.

The integration of Laser Cut Carbon Fiber technology into manufacturing processes has the potential to revolutionize various industries, from aerospace and automotive to sporting goods and consumer electronics. The ability to produce stronger, lighter, and more complex components with greater efficiency and lower production costs has already sparked significant interest and investment from companies looking to stay ahead in the competitive global market.

As a leading provider of laser solutions, [Company Name] is at the forefront of driving the adoption of Laser Cut Carbon Fiber technology among manufacturers worldwide. With its commitment to outstanding innovation and relentless pursuit of excellence, [Company Name] continues to push the boundaries of what is possible with laser technology, empowering its customers to embrace the future of manufacturing.

The emergence of Laser Cut Carbon Fiber technology marks a significant milestone in the evolution of manufacturing processes, offering unprecedented levels of precision, speed, and flexibility that are poised to transform the way products are made. With the support and expertise of technology leaders like [Company Name], the industry is ready to embrace a new era of innovation and efficiency.